Why Choose VMV

VMV Advantages

- 1. VMV brand is strong

- 2. Scientific and technological innovation has achieved results

- 3. Product quality is guaranteed

- 4. The product has an advantage in cost performance

- 5. Many achievements and rich project experience

- 6. Sales service is very professional

- 7. Product supply is guaranteed

- 8. Excellent corporate culture

1. VMV brand is strong

VMV brand was established in 1998. Over the years, we have been rooted in the fields of thermal oil, steam, chlorine-alkali and other media working conditions, focusing on the research and development and production of bellows valves, steam traps and regulating valves, and have grown into one of the benchmark companies in the industry’s professional fields. VMV Newton brand has strategic partners and brand agents in more than 30 countries and regions including Europe, the United States, Southeast Asia, and the Middle East, and its reputation and popularity are increasing year by year.

2. Scientific and technological innovation has achieved results

2.1 Intellectual property drives innovation:

There are more than 40 valid patents, 4 valid invention patents, 19 utility patents, 19 appearance patents, 4 software copyrights, and the implementation conversion rate of patent results is 100%. Among them, the invention patent of wet chlorine special valve fills the domestic gap; the zero-leakage new energy special bellows stop valve plays an innovative leading role in the industry.

2.2 Talent-driven innovation:

In 2019, a research and development center was established in Shanghai, and a total of 3 senior engineers were introduced to successfully develop a series of high-end steam trap products and provide users with system solutions. Key technologies are derived from independent research and development, and many indicators exceed similar international products.

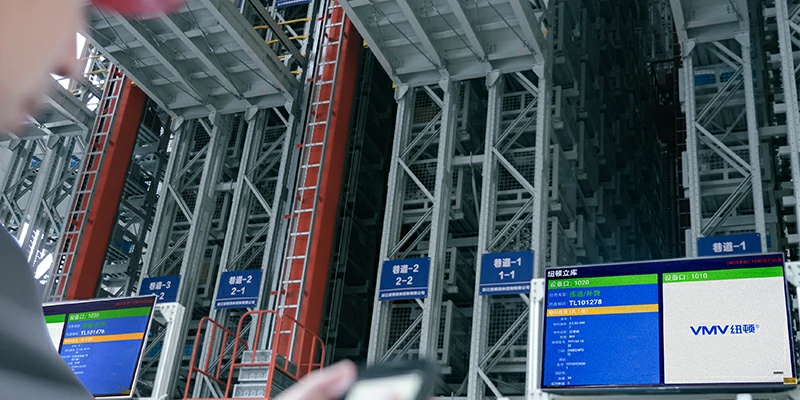

3. Product quality is guaranteed

VMV Newton products cover ISO9001/14001/18001 systems and have passed national TS special equipment A-level certification, CE certification, TUV ISO15848, CCS, EAC and other international certifications. The company has officially opened the headquarters AI intelligent manufacturing base with a total construction area of 75,000 square meters, and built a 2,500 square meter three-dimensional warehouse. It cooperates with global leading intelligent manufacturing companies such as Japan’s FANUC and Germany’s KUKA to create a digital factory from three-dimensional warehouses, AGV transfer, robot processing units, intelligent assembly, intelligent testing, intelligent spraying lines to intelligent warehousing.

The company has established a professional system solution and product R&D center, with a three-dimensional simulation manufacturing test design system and a high-temperature dynamic simulation test device. It has jointly developed fully automatic testing equipment with a leading European intelligent testing equipment company, with a detection accuracy of 1ΔP.

All products produced by the company have undergone four strict tests to ensure a 100% factory qualified rate. The first test is the bellows test, the second is the core sealing component test, the third is the seal test, and the fourth is the shell test. It has leading advantages such as safe structure, excellent design, zero leakage, and high energy saving rate.

4. The product has an advantage in cost performance

4.1 High cost performance.

VMV Newton steam and thermal energy series valve products are extremely cost-effective, and the product design fully considers safety margins and safety.

4.2 Long history.

VMV Newton has reached cooperation with well-known domestic and foreign companies to provide them with overall solutions for steam and thermal energy systems and complete sets of high-quality products, and has accumulated application experience and usage data in dozens of industries.

4.3 Integration of the industrial chain.

In 2018, 30 acres of land was acquired in Qingtian to build a green casting industrial park to achieve a strong integration of the upstream and downstream of the supply chain. Newton’s castings have achieved self-sufficiency and have obvious advantages in quality, delivery time, price, etc. It has now formed an intelligent manufacturing pattern with Yongjia as the headquarters and Qingtian as the supporting facilities.

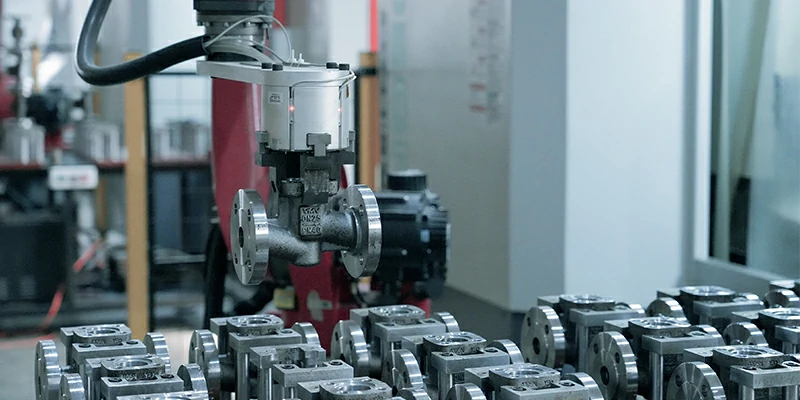

4.4 High degree of intelligence and digitization.

Truss robot processing flexible units, U-shaped production and manufacturing units, processing special machine manufacturing, intelligent detection, the first application of pump and valve cloud platform, ERP/MPR/CRM/MES/APS as one of the information capabilities will provide users with cost-effective products and services.

5. Many achievements and rich project experience

VMV Newton’s core products are widely used in new energy, new materials, petroleum, chemical, pharmaceutical, food, papermaking, metallurgy, electric power, military and other industries, and have performed outstandingly in recent years.

6. Sales service is very professional

6.1 Business model innovation.

The development model has initially transformed from a “traditional valve product manufacturer” to a “system overall solution” service provider, realizing the full process service of “on-site investigation, solution design, full range of product intelligent manufacturing, installation and operation monitoring”.

6.2 Build professional service capabilities.

Hire industry experts, strengthen cooperation with scientific research institutions, and serve every customer and partner with all our strength.

6.3 Product after-sales guarantee.

VMV Newton steam series valve products are guaranteed to be repaired, returned or replaced within 18 months after leaving the factory due to quality problems. VMV Newton can remotely assist customers to solve problems in a timely manner, greatly improving the after-sales response speed and ensuring that every user’s feedback can get a solution within 24 hours.

7. Product supply is guaranteed

7.1 VMV Newton has connected the upstream and downstream of the industry. It has a 15,000 square meter casting base in Qingtian. It has the internationally leading coated sand casting process and silica sol process. The advanced process flow and efficient and scientific quality management system ensure that VMV Newton has a fast delivery speed and is able to provide customers with highly competitive delivery dates.

7.2 It has production processes, processes and equipment for special valves for new energy and new materials. The advanced casting process ensures the output rate and fast delivery of the main materials. The exclusive process flow, equipment and production line can guarantee fast delivery to the greatest extent and meet the installation requirements of emerging industry equipment.

8. Excellent corporate culture

VMV Newton’s corporate mission is “System Safety, Intelligent Resource Saving”, and we will do our best to contribute to our customers. We focus on talent cultivation, experimental research results and technological innovation, business summary and cultural accumulation, create high-quality value, and work together for the sustainable development of society.