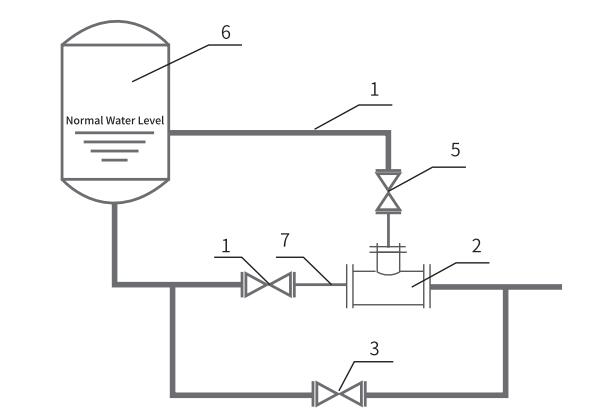

Description

Working Principle

After the drainage flows through the specially designed front-end valve core and is blocked, it enters the valve chamber. The liquid level in the container slowly rises to the interface of the phase change tube, and the phase change tube changes from a vapor phase signal to a liquid phase signal. At this time, the front end drainage and liquid phase pipe drainage mix and flow towards the designated rear end throat. Due to the unchanged throat area setting, the maximum drainage displacement occurs when the liquid level rises to the required normal water level (the rear valve core is the control expansion end); When the liquid level decreases, the steam consumption signal increases and enters the regulator, reducing the effective flow area of the throat drainage and the drainage discharge, thereby achieving the purpose of controling

the water level.

Features

- Phase change tube (signal tube): To collect vapor and liquid phase signals based on the liquid level.

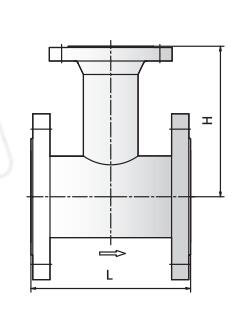

- Self regulating liquid level controller: The main equipment for controlling the liquid level.

- Bypass valve: A gate valve that corrects errors caused by inaccurate parameter provision.

- Inlet valve: A gate valve.

- Steam valve: A gate valve.

- Heater

- Connection short pipe

llustration