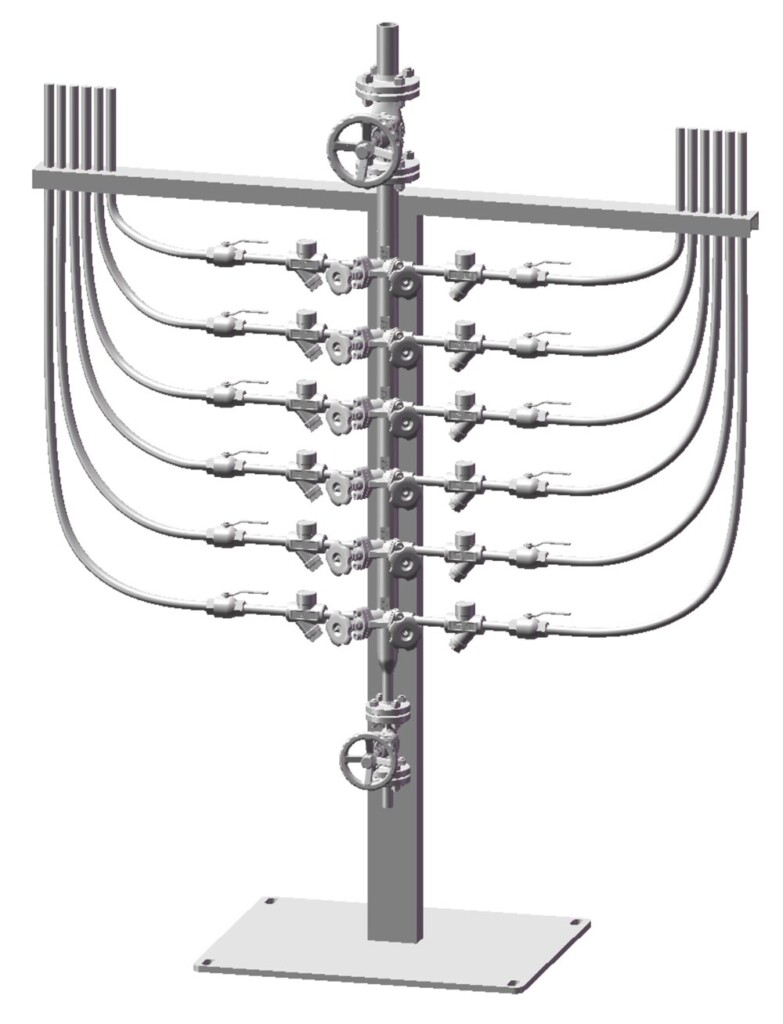

Description

Product Description

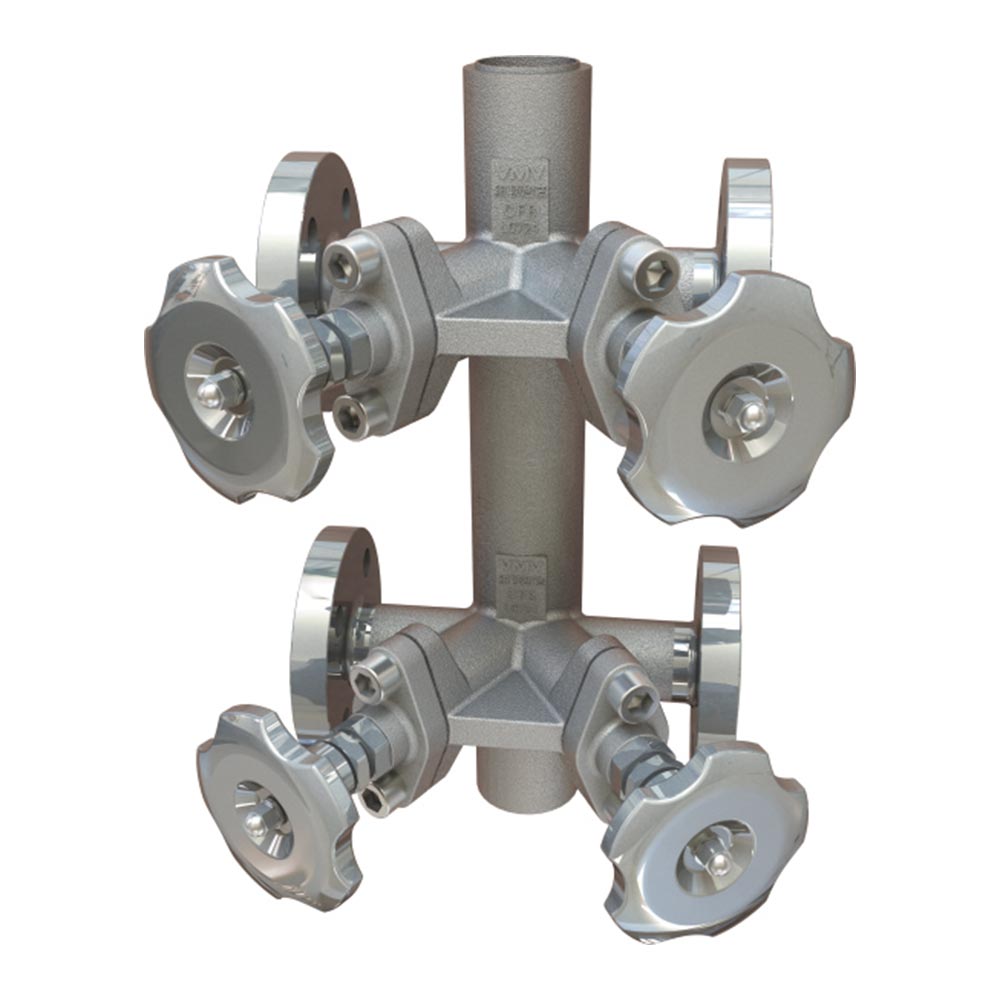

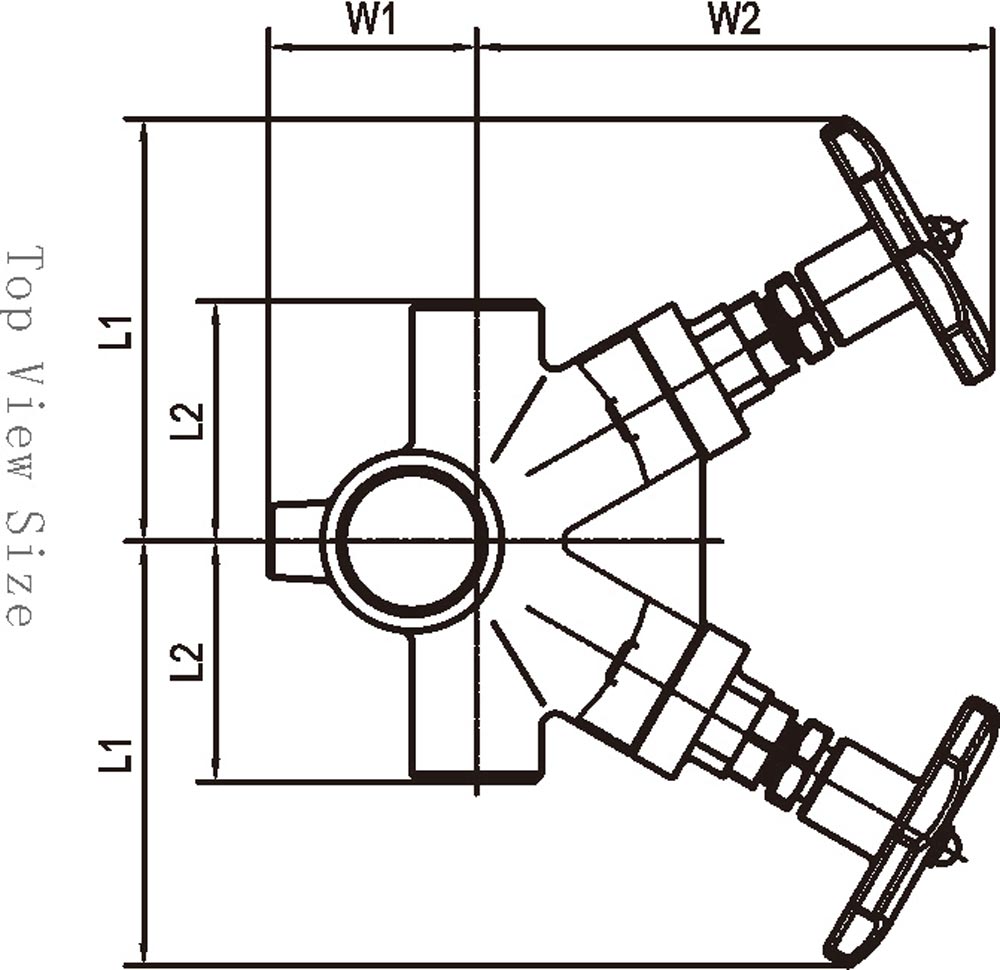

VMV’s “Condensate Manifold” integrates all components required for it (steam traps, manifolds, valves, etc). All components are installed on the base bracket, and the manifolds are scientifically distributed on both sides to provide a compact, easy to disassemble centralized positioning assembly. The Body is made of corrosionresistant material CF8, which is suitable for highend mainfolds, instruments, chemical corrosionresistant pipes and pipeline heating. The instrument heating recovery pipes can be connected by ferrules.Structural Featurest

- Integrated design, solid structure, shorten on-site construction time

- Maximize saving installation space and easy maintenance

- Integral ball seal face and V-line seal seat Ensure perfect sealing

- Adopting stainless steel bellows design,it is easily opened and becomes durable and non-leaking.

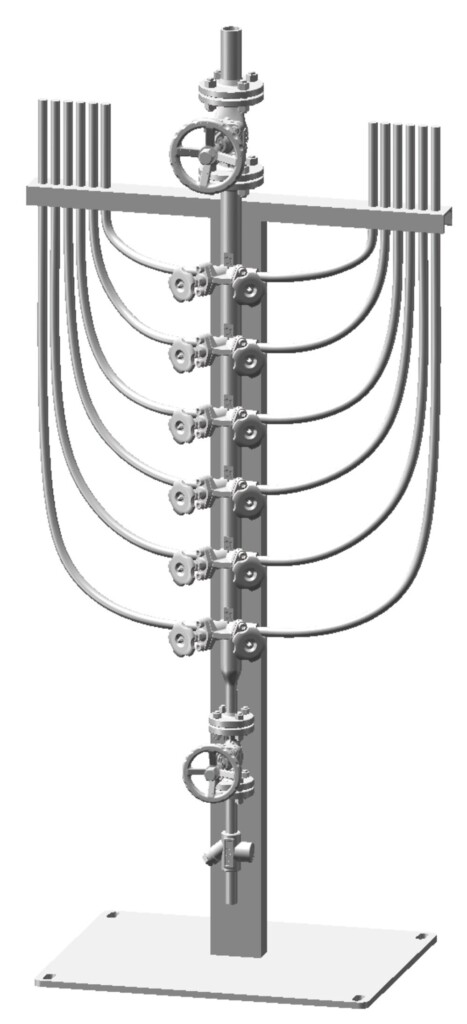

Bellows Stainless Steel Steam Distribution Manifolds

Steam Inlet

Bellows Globe Valve

- Equipped with bellows globe valve for steam inlet

- Ensure zero leakage and maintenance free at the packing

- Line Sealed Seat

- Improve sealing performance

- Precision machined stainless steel handwheel

- Ergonomically designed

Manifolds Stainless Steel Material

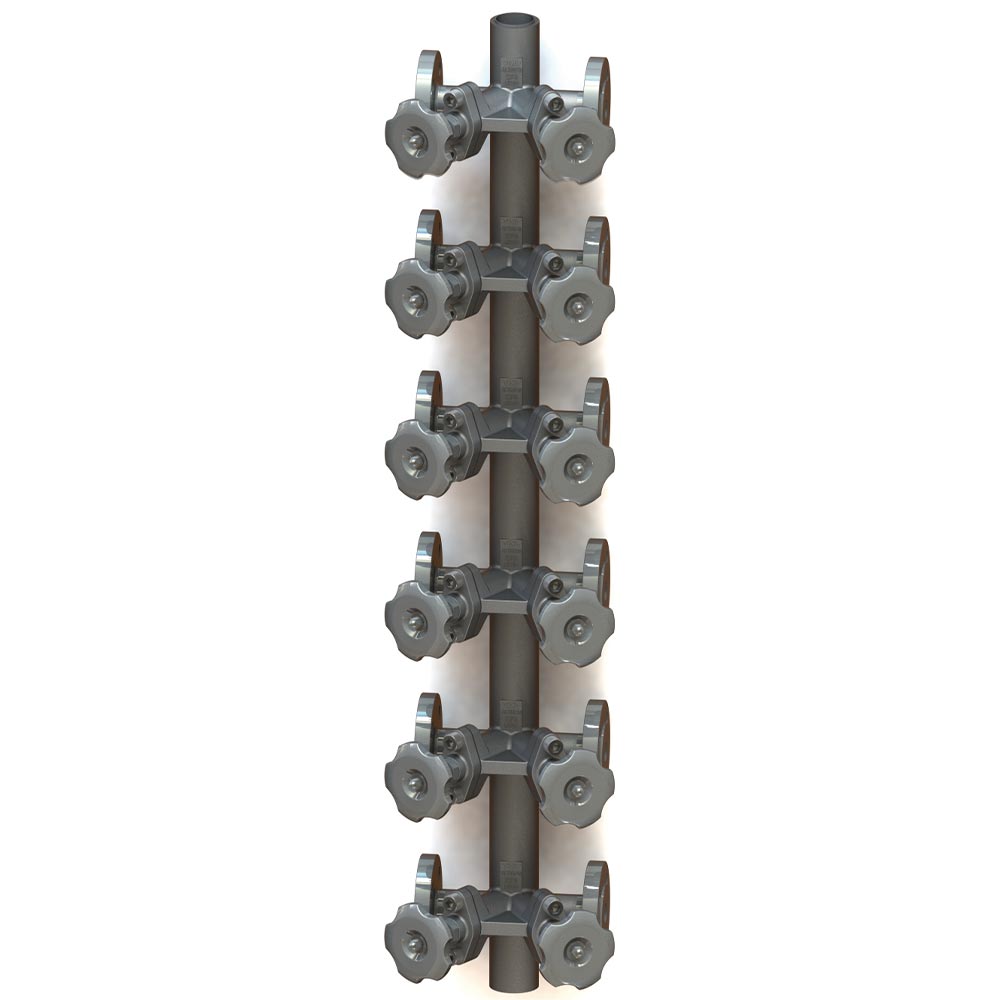

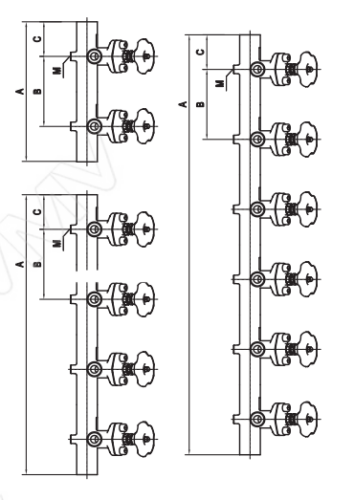

- Centralize all steam distribution valves

- Standardized and integrated skid-mounted combination

- Reduce construction time and cost for on-site installation

- Configure VMV bellows globe valve and steam trap

- Built-in bellows globe valve ensures zero leakage at packing

Manifolds Assembly Base

- Optional customized steel base and frame Manifolds on

both sides for optimal installation sequencing - Easy on-site installation

Steam Trap

- Bottom configuration steam trap

- Remove condensed water

Bellows Stainless Steel Condensate Collection Manifolds

Condensate Outlet

Bellows Globe Valve

- Condensate outlet configuration

- Bellows globe valve

- Ensure zero leakage at the packing

- Maintenance free

- Line Sealed Seat

- Improve sealing performance

- Precision machined stainless steel handwheel

- Ergonomically Design

Steam Trap

- Configure thermodynamic, thermostatic,

bucket inverted and other types of steam traps

Manifold Stainless Steel Material

- Centralize all condensate recovery valves

- Standardized and integrated skid-mounted combination

- Reduce construction time and cost for on-site installation

- Configure VMV bellows globe valve and steam trap

- Built-in bellows globe valve ensures zero leakage at packing

- Spherical line sealing structure of valve core

Manifold Assembly Base

- Optional customized steel base and frame

- Manifolds on both sides for optimal installation sequencing

- Easy on-site installation