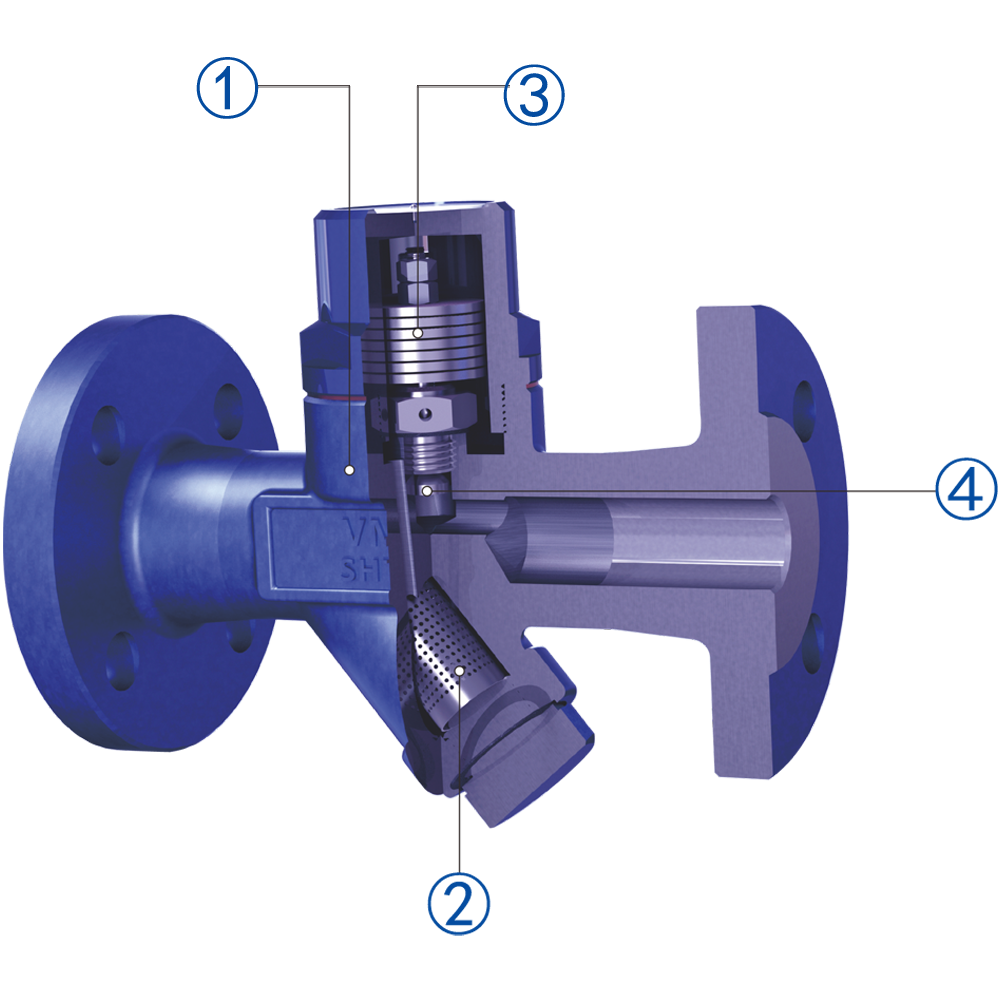

A105 material is adopted, and the corrosion allow-ance, minimum shell wall thickness, pressure and temperature grade are fully considered in the design

Effectively prevent pipeline impurities into the valve, ensure the normal work of the trap, and prevent water hammer damage to internal components.

The imported bimetal sheet guarantees the specific bending value Temperature structure can be adjustablePrecise temperature control

Unique linear sealing closing system and micron class high precision seat and spool ensure reliable closing without steam leakage

Bimetallic trap is characterized by large undercooling, long life, good energy saving effect, water hammer resistance, beautiful appearance and so on. It is widely used in heat tracing and steam pipelines.

The technical advantages of VMV traps are unique and resonable structure and high precision internal parts

A105 is used for VMV bimetallic trap boday and bonnet. The condensate discharge temperature has been setted to 120-130C°before delivery.And it can be adjusted as required.

The bimetallic steam trap adopts a line sealing closing system,which has no original steam leakage, no noise, good air exhausting capacity, and makes full use of the sensible heat of condensed water, resulting in good energy saving effect.

Bimetallic trap works on the difference in temperature between steam and condensate. When the condensed water stays in the pipeline due to the high temperature, the bimetal deforms when the temperature of the energy to be released decreases, and the valve seat opens to discharge the condensed water. The user can adjust the discharge tempera-ture of the trap at any time according to the season.

.

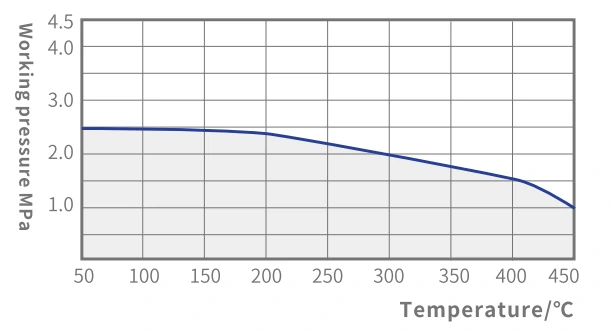

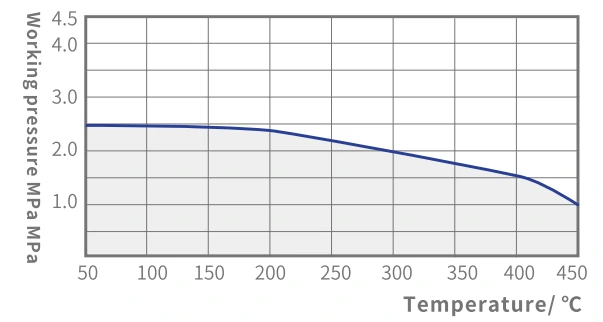

The bimetallic trap drains continuously. The normal discharge temperature of SHT16 is 120-130°C, and the discharge temperature of SHT32 is 140-150°C (users can adjust it by themselves). If there is a requirement for degree of under cooling, please indicate it when order-

ing. The back pressure rate of bimetallic steam traps can reach 50% (back-end pipeline pressure/steam pressure), which is not suitable for closed recovery system, but suitable for pipeline and heat tracing system to remove condensate. In general, the safety factor is 2-3 times.

Notice: The amount of condensed water and differen-tial pressure of steam-using equipment are important indicators for selection. The same type of trap will increase its displacement with the increase of differential pressure. Check the displacement curve in detail. Please do not mistake it for a trap with larger diameter has larger

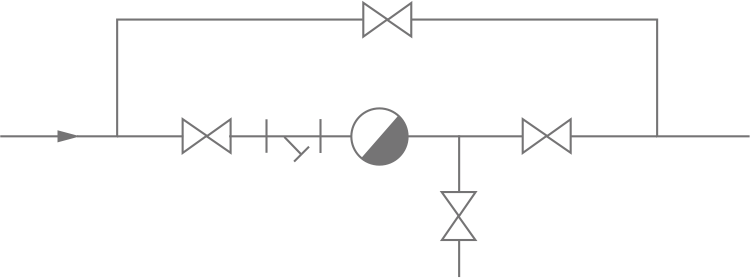

The bimetallic trap can be installed at any position on the pipeline or equipment. The basic configuration of the trap is shown in the figure above.

Zhejiang Newton Fluid Control Co.,Ltd.

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…