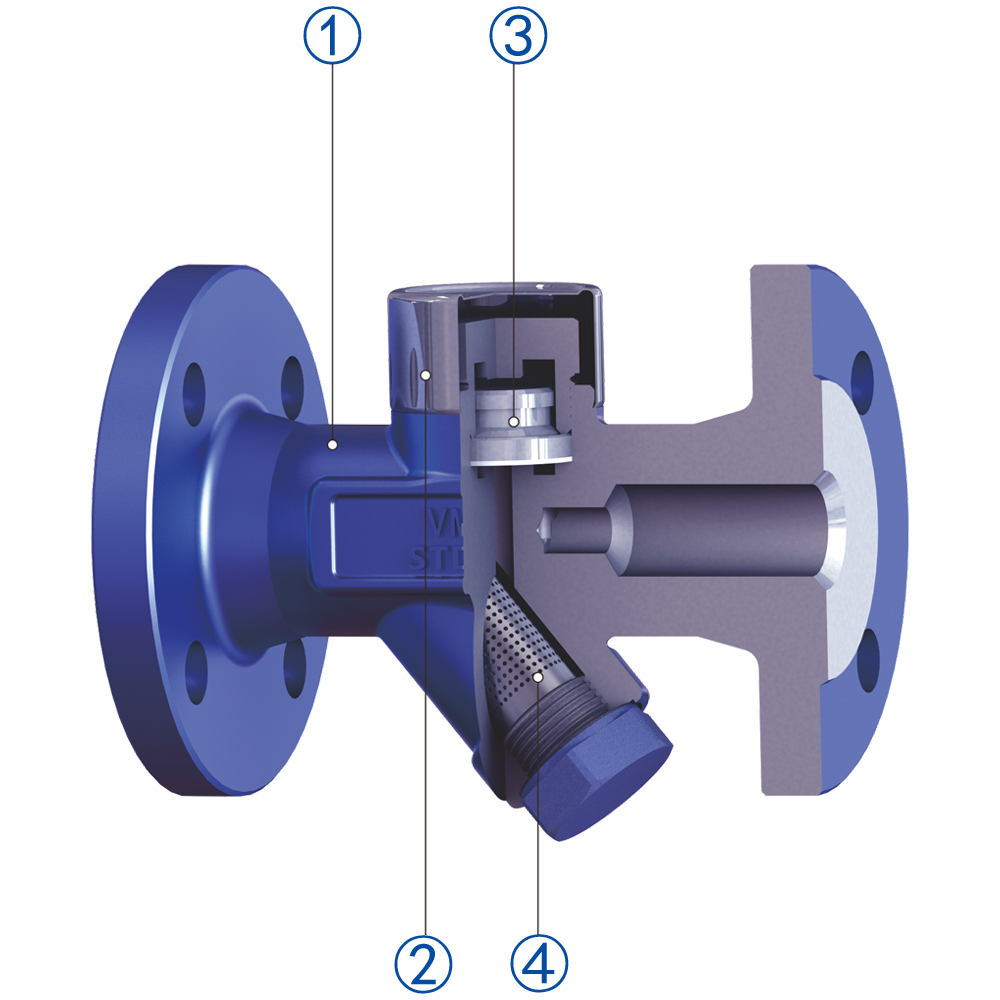

A105 (15CrMo) material is used, and corrosion allow-ance, minimum shell wall thickness, pressure and temperature grade are fully considered in the design.

Stainless steel thermal insulation cover ensures that the transformer room is not affected by the outdoor environment and prevents invalid actions.

The valve seat and valve plate are made of martensitic stainless steel with unique heat treatment. According to different working conditions, two kinds of condensate removal solutions of low temperature (less flash steam) and saturated water can be provided

Effectively prevent pipeline impurities from entering the valve, make sure the trap valve is working properly.Built-in Filter

Thermodynamic steam traps are widely used in low, medium and high pressure steam pipelines, process heat tracing, and small displacement equipment due to their small size, large displacement, energy saving, long life, and low temperature resistance.

The technical advantages of VMV steam traps are unique and reasonable structure, high-precision internal parts, changeable valve seat.

VMV thermodynamic steam trap uses A105 for the low pressure trap body and 15CrMo for the medium pressure trap body.

According to the Bernoulli equation, it has been repeatedly calculated and finally finalized through a large number of experiments. The product is available in low temperature and saturated versions. The low-temperature type discharges the condensate at a lower temperature (higher degree of subcooling) and has less noise, but the air discharge capacity is poor; the saturated type discharges the condensed water close to the saturation temperature (low degree ofsubcool-ing), with high noise and good air discharge capacity.

Thermodynamic steam traps operate on the difference in flow rates between steam and condensate. When the condensate passes through the valve seat, the flow rate is small, and the valve plate is opened to discharge the condensate water; when the steam enters the valve seat, the valve seat is closed due to the large flow rate.

VMV Newton has broken through the problems that thermodynamic steam traps are not energy-saving, noisy, and discharges raw steam, and has become the best steam pipe guide steam trap. Its advantages are small size, long life, reliable action, convenient maintenance, and low noise ( Low temperature type) no original steam leakage

.

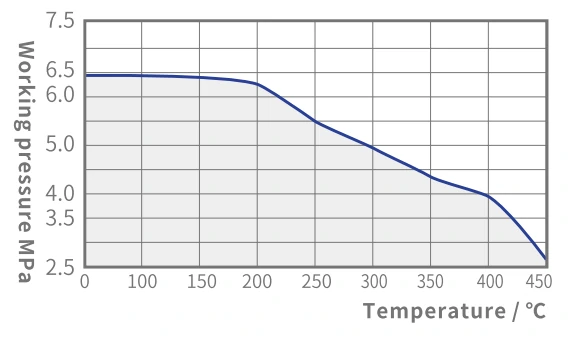

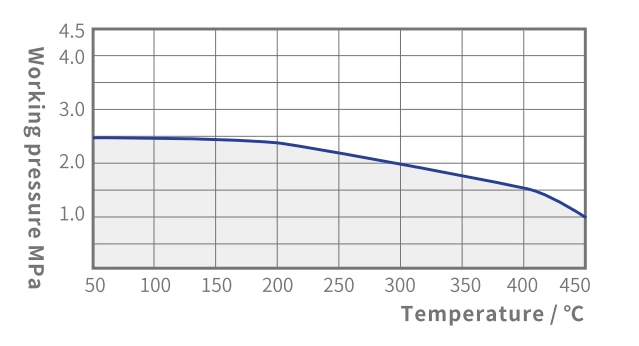

The thermodynamic steam trap is intermittently drained, and the normal product STD16/STD42 steam trap has a subcooling degree of 5-10°C. The back pressure rate of the thermodynamic steam trap can reach 80% (rear pipe pressure/steam pressure), and it is suitable for pipes and small equipment to remove condensate. In general, the safety factor is 2-3 times.

Special reminder: The amount of condensate and the differential pressure of the steam-using equipment are important indicators for selection. The same type of trap will increase the displace-ment with the increase of the differential pressure. See the details on displacement curve. Please do not mistakenly think that the large

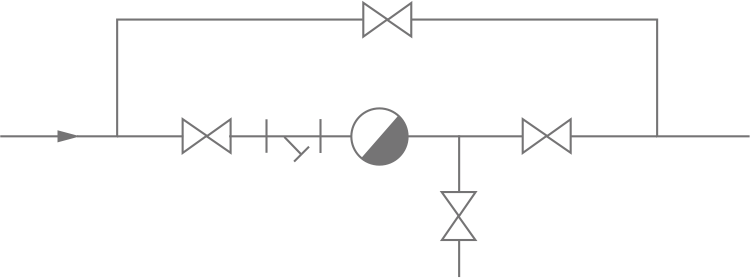

Thermodynamic steam traps can be installed arbitrarily at the bottom of the pipeline or equipment. The basic configuration of the steam traps is shown in the figure above.

Zhejiang Newton Fluid Control Co.,Ltd.

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…