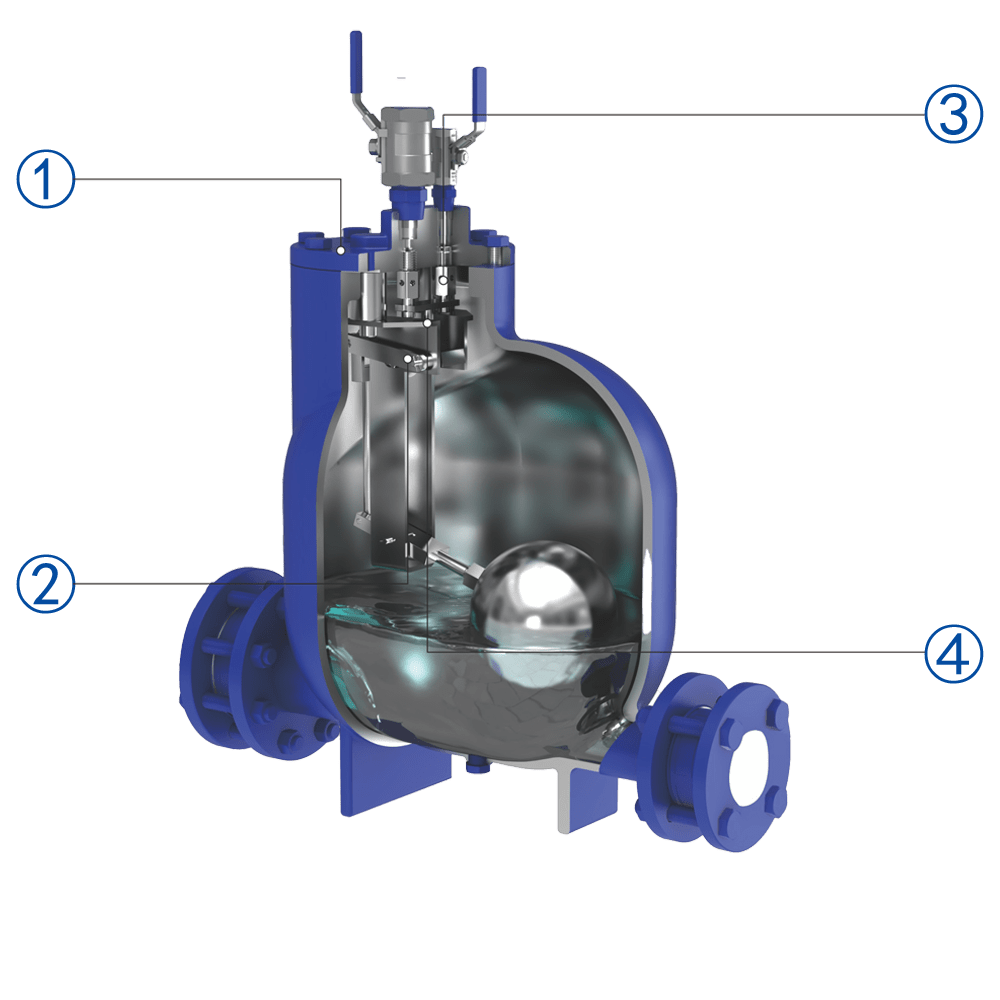

Open the valve cover at a glance without removing the pipe connection

High temperature alloy spring is used for long-term stable operation at 540°C

The valve seat and valve core are made of stainless steel, and the closing pair adopts flexible closing system with small wear, reliable closing and long service

Welding of key partsThe accuracy of key parts of stellite alloy can reach μm levelThe key parts are welded with Stelli alloy, and the precision of key

1、 Condensate delivery capacity kg / h

2、 Back pressure (head of delivery) MPa

3、 Power steam (air)

4. Water inlet normal diameter DN

5. Water outlet normal diameter DN

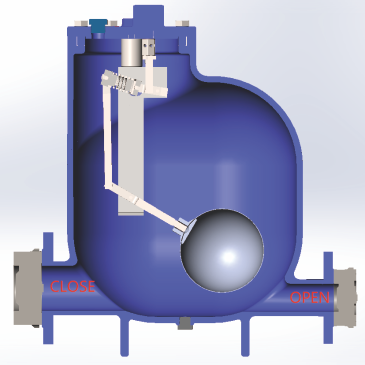

VMV condensate recovery pump (pump trap) first came from foreign technology, originally meaning “pump trap”, also known as mechanical power pump. It uses the principle of steam trap and relies on steam, air and other gases as power to transport condensate from low-pressure area to high-pressure area, or from negative pres-sure area (vacuum) to normal pressure area.

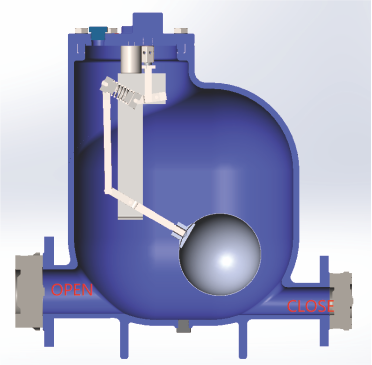

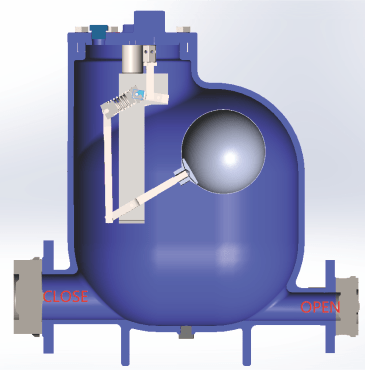

At the beginning, the water inlet check valve is opening, the water outlet check valve is closed due to high back pressure, the water start to enter the pump, and the floating ball is at a low level,with the rise of water level and the opening of exhaust valve, the floating ball reaches the highest controller and is in the switching critical

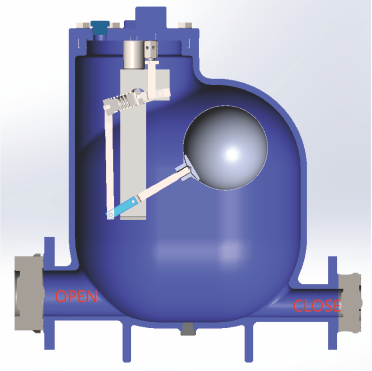

The controller starts switching at the high position and closes the exhaust valve: open the power steam(air), inject steam into the valve, and push the condensate in the pump to the high-pressure area under the steam pressure: at this time, the water inlet check valve cannot feed water due to the high pressure in the pump.

Design Standards

• GB / T22654-2008 Technical conditions for steam traps

• GB / T12251-2005 Test methods for steam traps

• GB / T12224-2005 General requirements for steel valves

| Nominal Pressure | PN16 (150LB) | Design pressure of valve body | 2.5MPa | Water inlet diameter | DN80 RF |

| Maximum Allowable Pressure | 1.6MPa /204℃ | Maximum Allowable Temperature | 300℃ /1.23MPa | Water outlet diameter | DN50 RF |

| Maximum Working Pressure | 1.05MPa | Maximum Operating Temperature | 250℃ | Steam outlet diameter | 1” RC |

| Maximum Power Steam Inlet Pressure | 1.05MPa | Steam (Air) Consumption | Steam 5kg / T condensate air 7.6m3/T condensate | Steam inlet diameter | 1/2” RC |

| Valve Body,Cap | WCB | Float | 304 |

| Valve Seat | 420 | Control Rack | 304+Stellite |

| Valve Core | 440C | Fastener | Carbon steel grade 8.8 |

| Spring | Ni Base Superalloy | Gasket | SS304+flexible graphite |

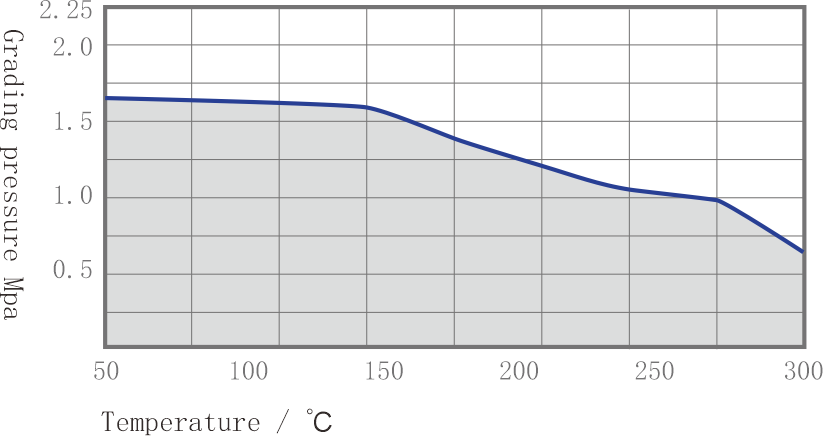

WCB/A105Material PN16 valve shell pressure temperature rating

Zhejiang Newton Fluid Control Co.,Ltd.

Comprehensive Steam and Thermal Energy System Solutions Manufacturer

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…