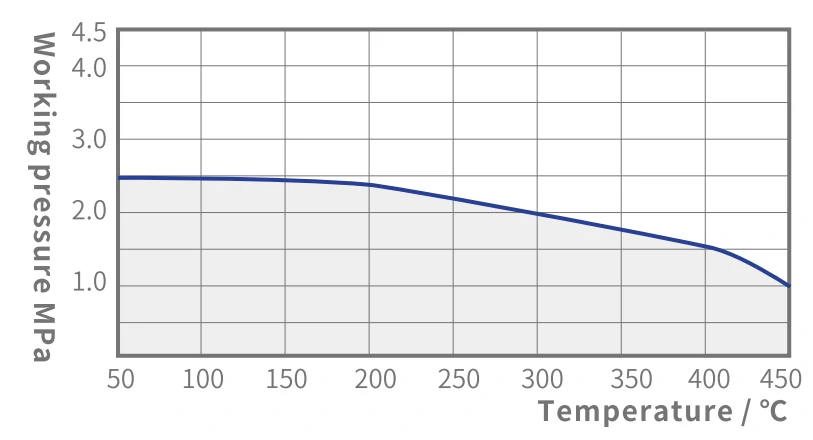

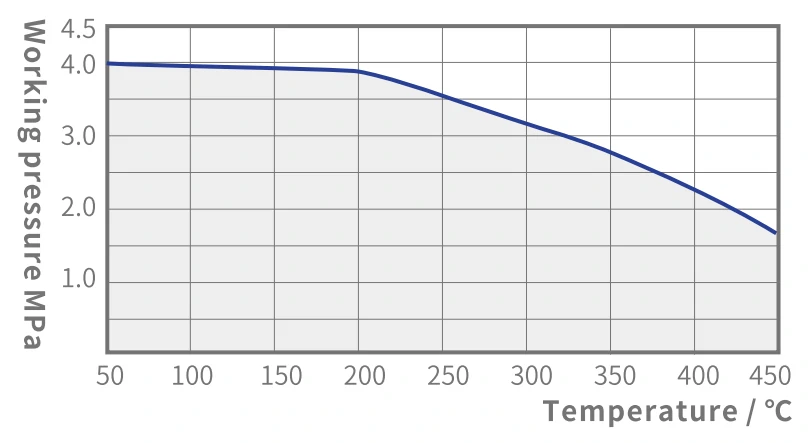

Using WCB material.Fully consider corrosion allowance, minimum shell wall thickness, pressure and temperature grade when design-ing

Prevents water hammer from damaging internals.Also suitable for superheated steam environment

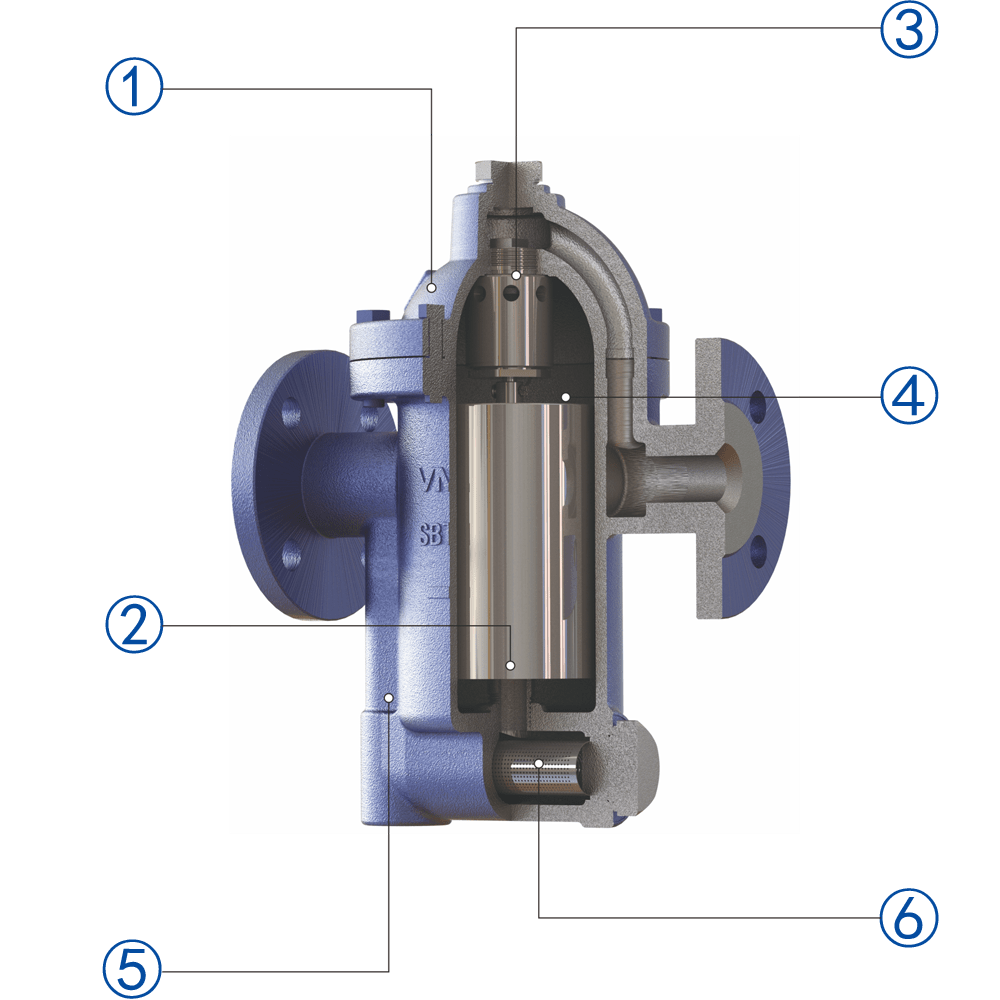

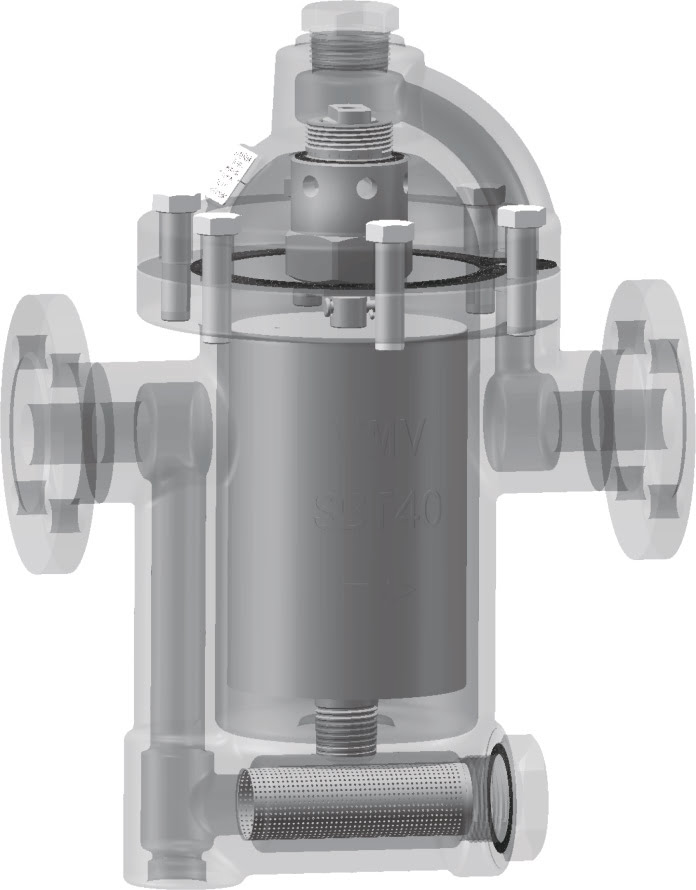

High-precision flexible pilot closing system Pilot valve guides the main valve to open and close

Small holes are left on the upper part of the bucket to remove air and other non-condensable gases to prevent the occurrence of steam lock the valve

The U-shaped flow channel design ensures that the inside of the valve body is in a water-sealed state.No raw steam leakage

Effectively prevent pipeline impurities from entering the valveMake sure the trap valve is

The pilot inverted bucket steam trap has the characteristics of large displacement, long life, good energy saving effect, water hammer resistance, and beautiful appear-ance. It is widely used in process heat tracing, jacketed heating kettles tank, reboilers and other equipment.

The technical advantages of VMV traps are: unique and reasonable structure , high-precision internal parts.

.

The pilot inverted bucket steam trap is intermittently drained, with a subcooling degree of 5-10C and a back pressure rate of more than 85% (back-end pipeline pressure/steam pressure). In general, the safety factor is 2-3 times when selecting, and 5-8 times for air separation units and drying cylinders.

The amount of condensed water and the differential pressure of the steam-using equipment are important indicators for model selection. For the same type of steam trap, the displacement increases with the increase of the differential pressure. See the details on displacement curve.

Special reminder: Please do not mistakenly think that a trap with a large diameter has a large displacement.

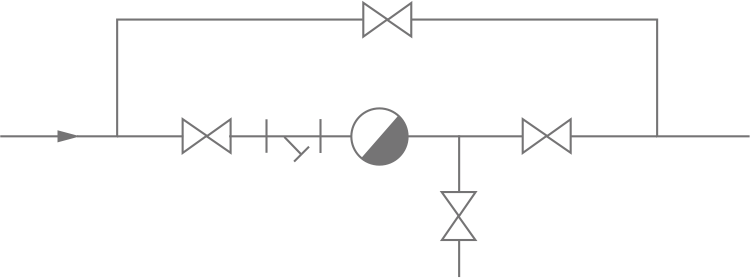

The pilot inverted bucket trap is installed horizontally at the bottom of the pipeline or equipment. The basic configuration of the trap is shown in the figure on the right.

In order to prevent the water hammer phenomenon after the water vapor in the pipeline is mixed, a check valve must be built in.

Zhejiang Newton Fluid Control Co.,Ltd.

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…