VMV V9000 series GLOBE straight-stroke bellows control valve is developed by Newton’s professional R&D team.In view of the conventional control valve, packing is easy to wear,leak externally, poor adjustment regulating, bellows seal is not durable and other phenomena, VMV has collected much operational condion informao and researched technically for the above phenomenon..Many tests have proved that the V9000 series can fully meet the users’ needs, especially applied in the petrochemical industry and high requirements for fresh air and other special conditions.

VMV equipped with either pneumac diaphragm actuator or electric actuator according to the user’s on-site energy

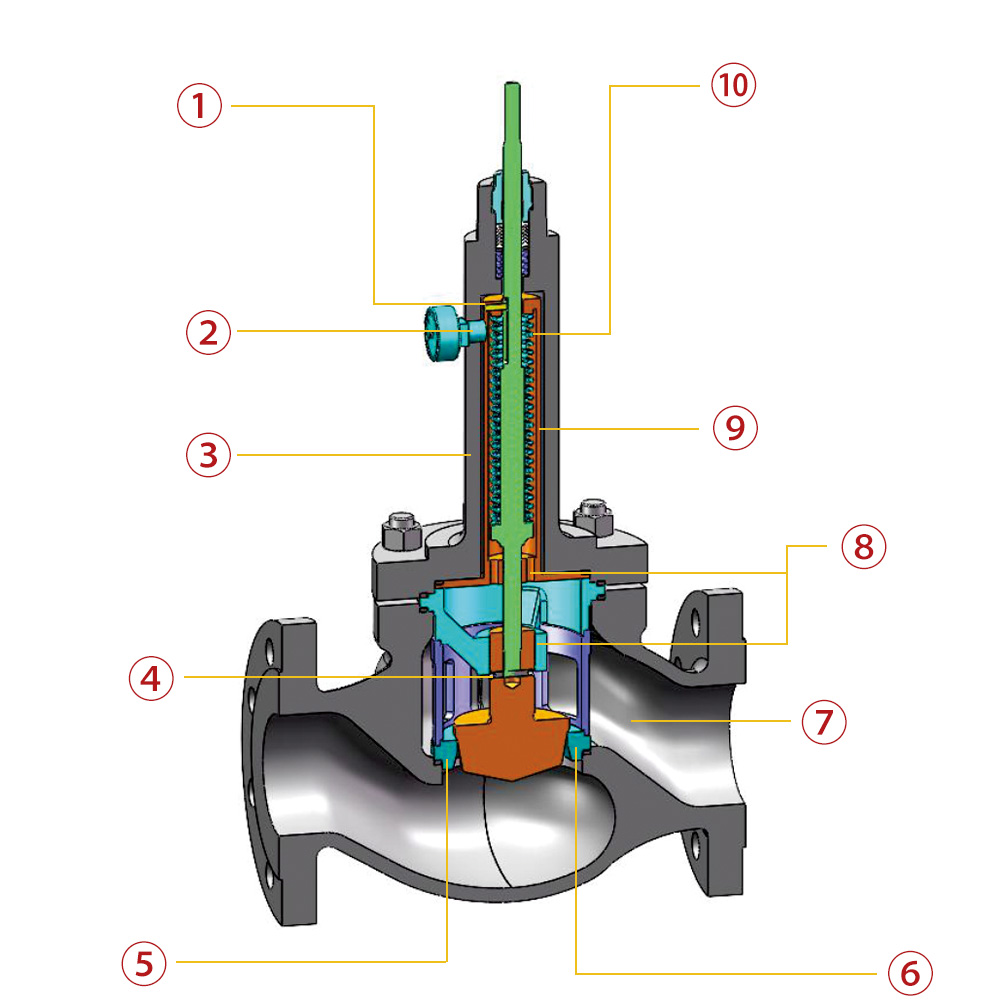

Single-seat control valve

The keyway on the valve stem is matched with the pin of the bellows sleeve. Forcing the bellows to move along the axis to prevent damage and increase the service life of the bellows.

A pressure gauge or pressure sensor can be connected to the detecon port on the valve bonnet for real-me monitoring of bellows leakage.

Lower external leakage risk.

The plug and stem are closely connected, and there is no relave moving gap.Effecvely prevent stem fague and fracture caused by the relave swing of the plug and stem.

Prevent the gasket from being overly compressed to achieve durable sealing without leakage.

By loosening the valve bonnet bolts, theinternal components of the valve can beremoved one by one, allowing for quickmaintenance and replacement of the valveseat and internal components on-site,thus saving the user’s maintenance me

Prevent the medium from directly impacng the bellows,improve the service life of the bellows.

The valve core operates smoothly, not prone to vibraon and scking,ensuring higher regulang precision.cc

Protects the bellows during handling,installaon, and operaon. Without bonnet parts, more convenient and fast to replace

Provide stable pressure load for bellows, reduce movement and increase the maximum allowable stress, thus improving the bellows service life and valve operaon accuracy.

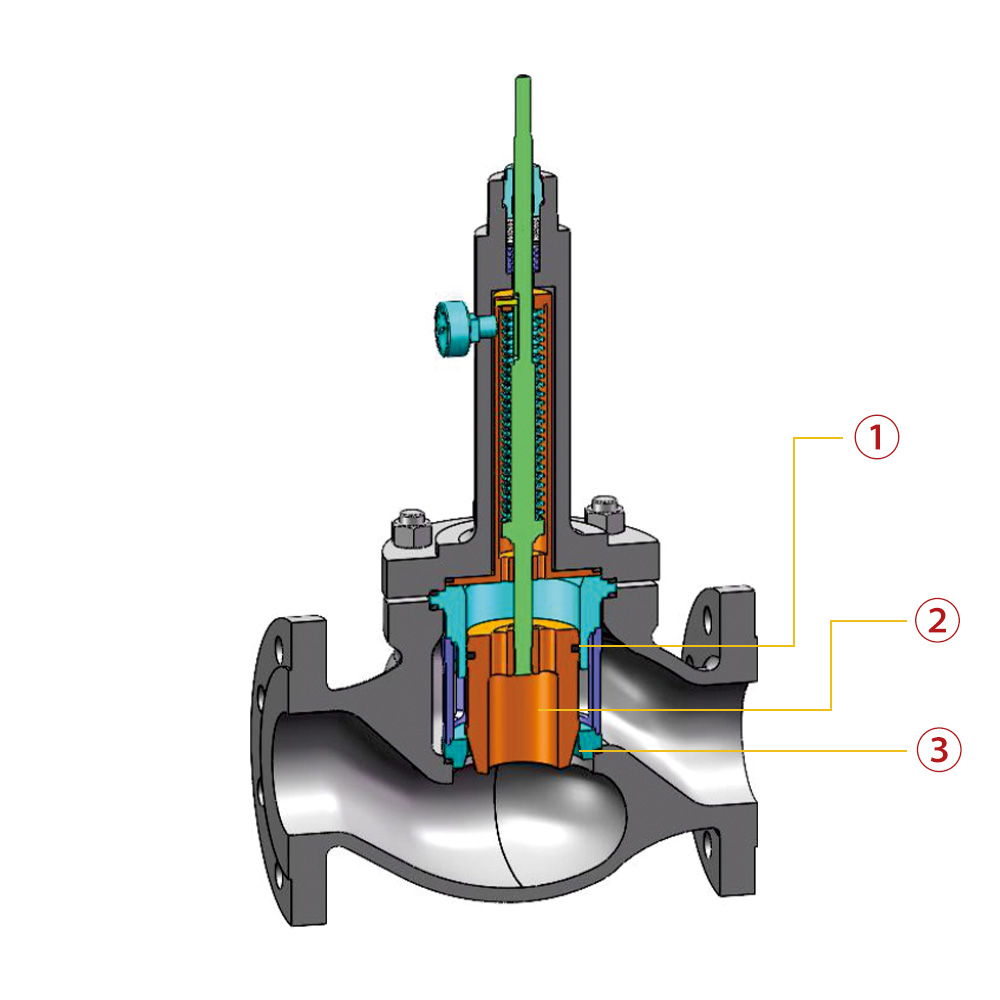

Balanced Single-Seat Bellows Control Valve

The wear-resistant piston ring sll has self-lubricang attemperatures above 200°C, making the valve not easy to stretch and sck during the long period regulang process, maintaining a seal class above level IV .

Low thrust overcomes the large pressure difference,has beer performance of overcoming differenal pressure.

The throling orifice is uniformly distributed on the surface of the valve core, allowing the medium to flow smoothly and stably, thus has higher regulang precision.

| Nominal diameter | DN15(NPS1/2)~DN300 |

| Pressure rang | PN16~PN420、Class150~Class2500 |

| Operang voltage (electric actuator) | 220VAC, 380VAC, 24VDC |

| Air supply pressure (pneumac actuator) | 0.4~0.6MPa |

| Operang temperature | -45~588 ℃ |

| Packing | V-type combinaon packing(≤300℃) Graphite combinaon packing(>300℃) |

| Rated Cv value | See table below |

| Flow characterisc | Equal percentage, linear, quick opening |

| Regulang | 50:1 |

| Leakage level | IV (metal hard seal)V (metal hard seal)VI (so seal) |

| Hysteresis | <1% |

| Dead zone | <0.8% |

| Allowable differenal pressure | See table below |

Zhejiang Newton Fluid Control Co.,Ltd.

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…