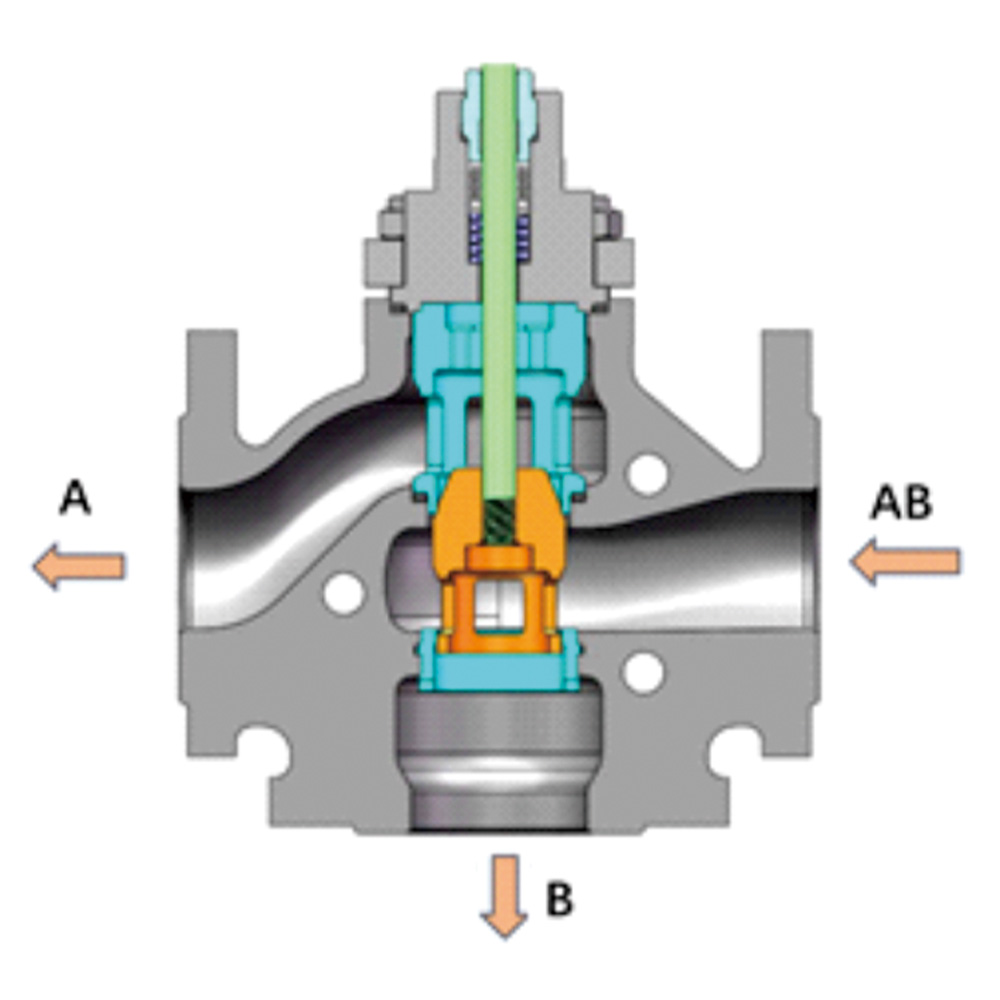

In the heang field, the three-way control valve is a common fluid control component that can replace two two-way control valves to regulate temperature and flow rate. These valves can be categorized as either combination flow and diversion type according to their functionality. Common issues with three-way control valves include difficulty in disassembling and replacing valve seats, packing wear and leakage, poor adjustment accuracy, stem breakage or detachment, and large leakage,which cannot meet operational requirements, lead to emergency in severe cases shutdowns, resulting in substantial losses for users.

Regarding above potenal hazards, the Newton R&D team conducted in-depth users’ sites and extensive informaon gathering regarding operaonal condions, as well as technological breakthroughs and through extensivevalidated tests and experiments making the designs, manufacturing, and batch deliveries of the V6000 series three-way control valves fully meet users’ requirements.

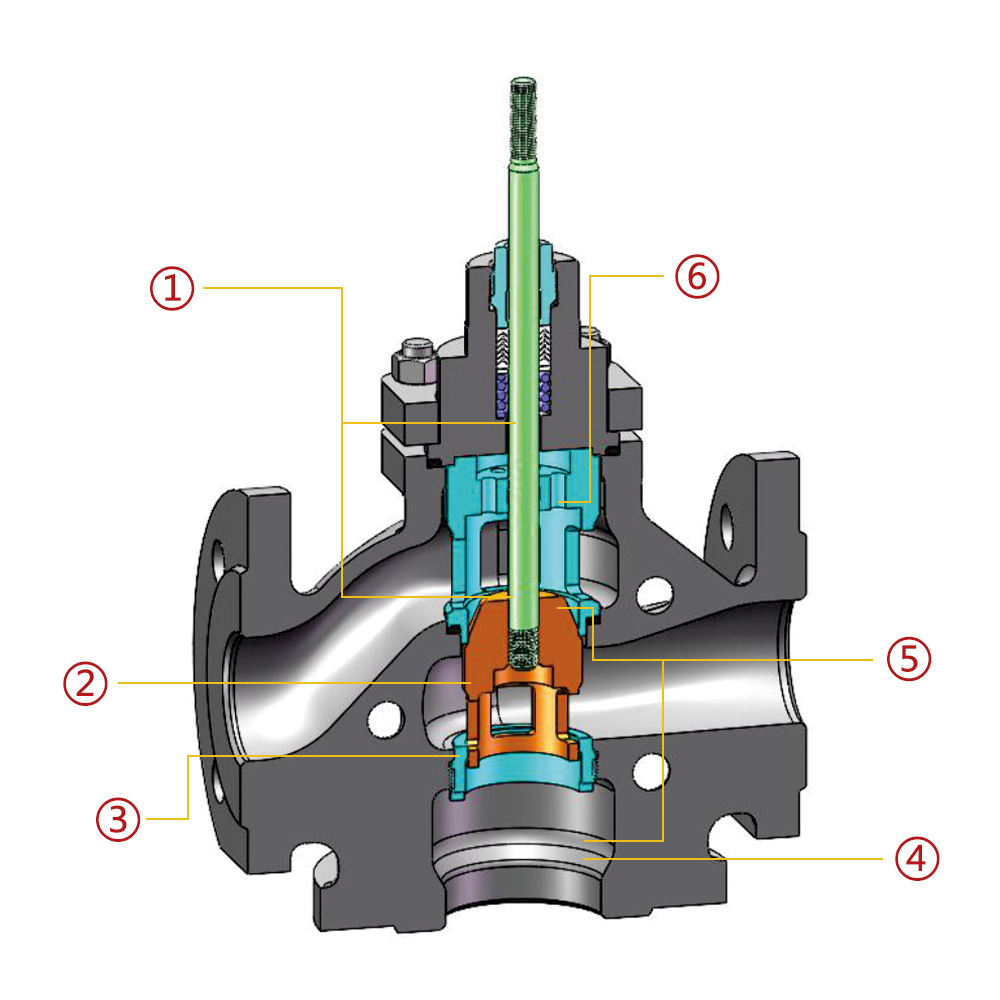

Keeping the packing and valve stem coaxial at all times can prevent abnormal wear of the packing caused by eccentricity,greatly improving the service life of the packing.

By loosening the valve cover bolts, the internalcomponents of the valve can be removed one by one,allowing for quick maintenance and replacement of the valve seats and internal components on-site, thus saving the user’s maintenance time

Prevent the gasket from being overly compressed to achieve durable sealing without leakage.

Lower leakage and hard seling can meet level V and above leakage requirements for a long time

The valve plug operates smoothly, not prone to vibration and sticking, ensuring higher regulating precision.

Provide a continuous and stable compressive force for the packing, allowing the packing to automacally compensate for wear during use, achieving long-term stable sealing.

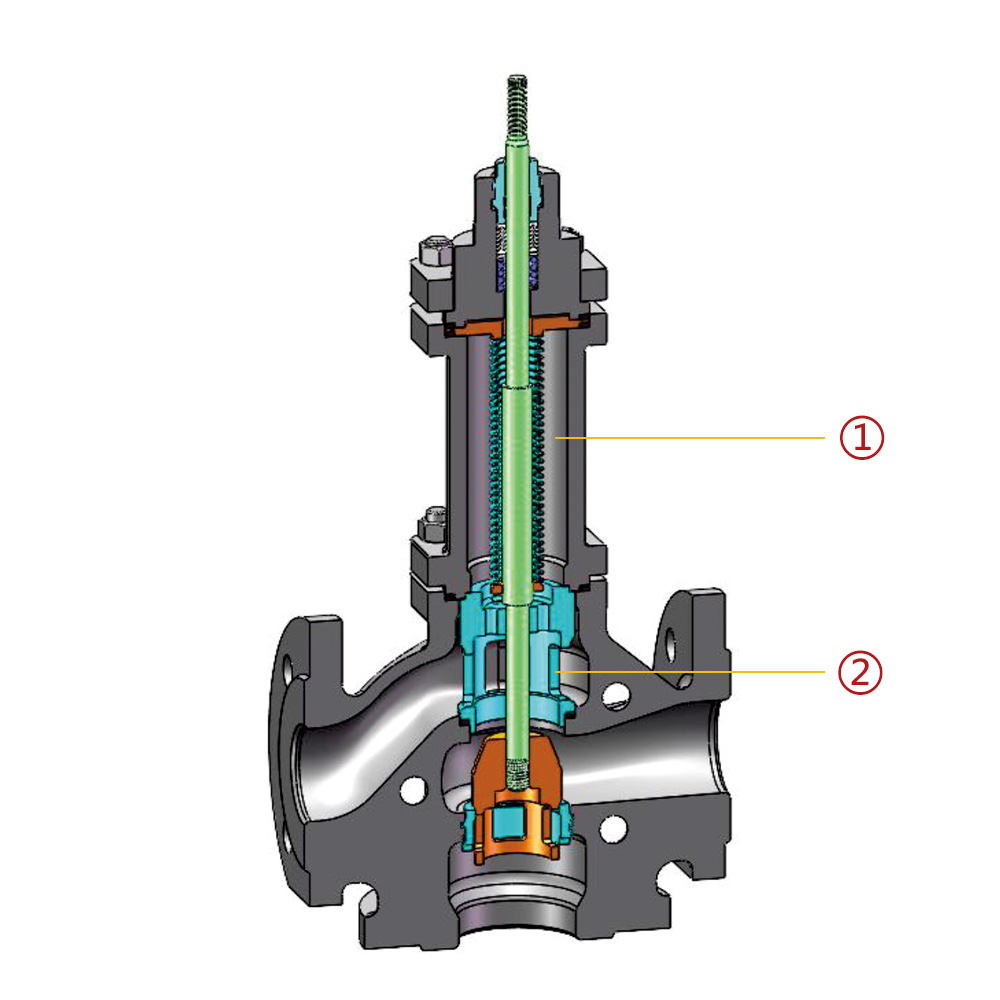

Provides a stable pressure load for the bellows, reducing movement and improving both the bellows’lifespan and the valves’operaonal precision.Compared to an internal pressure-bearing structure, an external.pressure-bearing structure increases the maximum allowable stress on the bellows, thereby enhancing its service life.

Prevents the medium from directly impacng the bellows, thereby increasing the service life of the bellows.

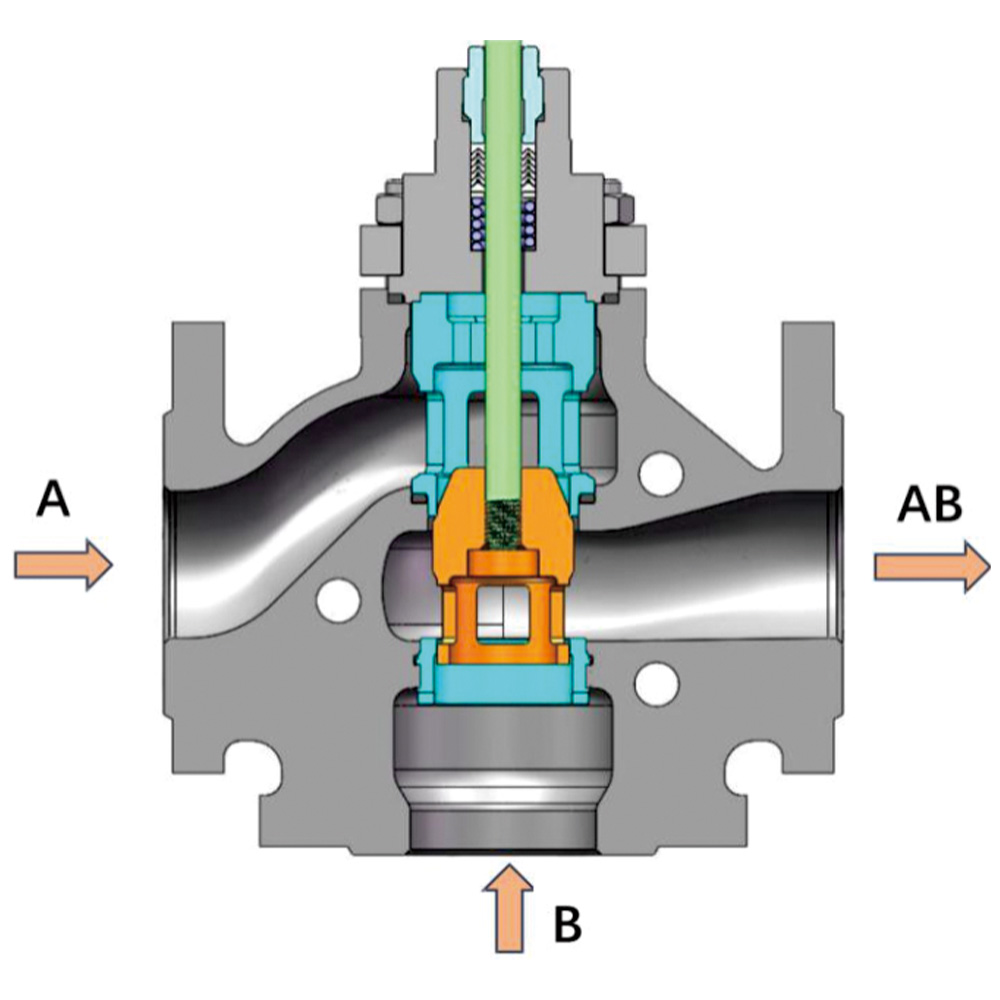

Three way combined flow type

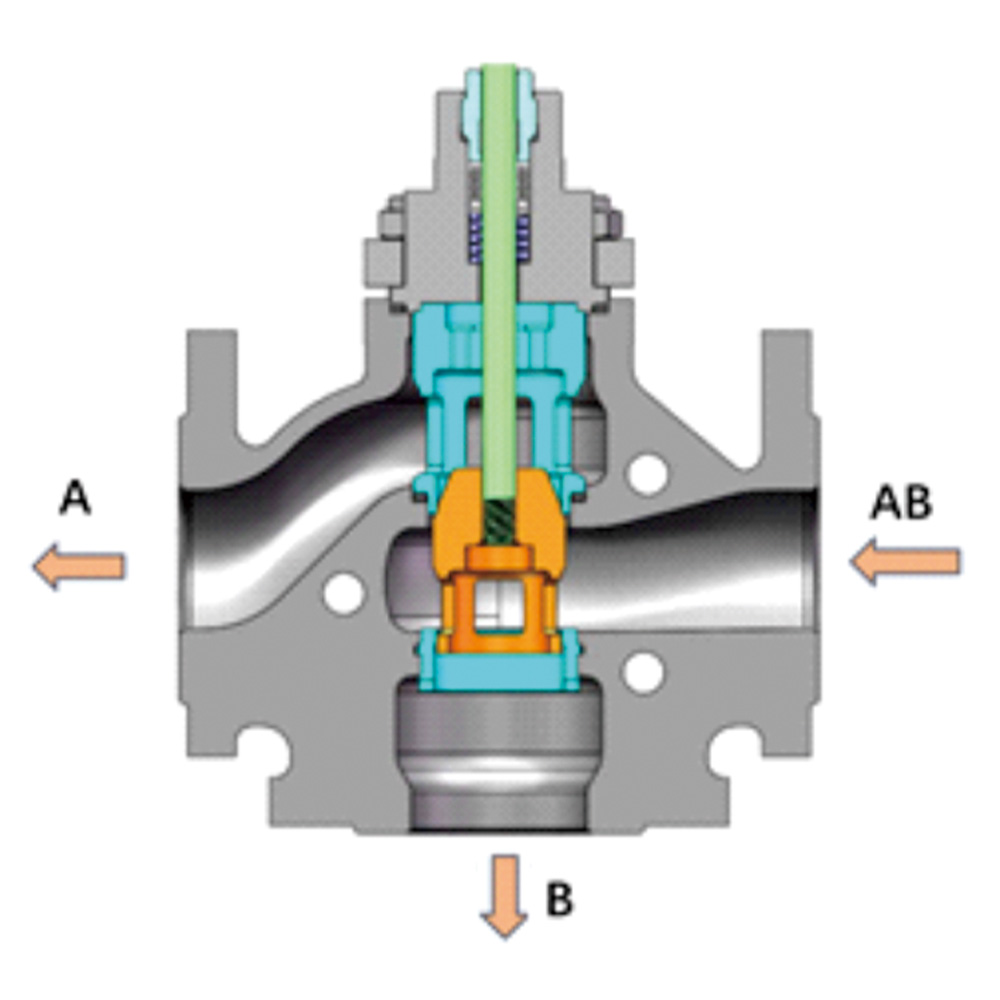

Three way diversion type(DN≤65)

Three way diversion type(DN>65)

VMV equipped with either pneumac diaphragm actuator or electric actuator according to the user’s on-site energy

| Nominal size | DN15(NPS1/2)~DN300 |

| Pressure rang | PN16~PN100、Class150~Class600 |

| Operang voltage (electric actuator) | 220VAC, 380VAC, 24VDC |

| Air supply pressure (pneumac actuator) | 0.4~0.6MPa |

| Operang temperature | -17~350 ℃ |

| Bonnet type | Standard type (-17~300℃) Radiator fin type(>300℃) |

| Packing | V-type combinaon packing(≤200℃) Graphite combinaon packing(>200℃) |

| Rated Cv value | See table below |

| Flow characterisc | Equal percentage, linear, quick opening |

| Regulang rao | 50:1 |

| Leakage level | Level IV (metal hard seal)Level V (metal hard seal)Level VI (so seal) |

| Hysteresis | <1% |

| Dead zone | <0.6% |

| Allowable differenal pressure | See table below |

Zhejiang Newton Fluid Control Co.,Ltd.

Comprehensive Steam and Thermal Energy System Solutions Manufacturer

What can we do for you?

1. 26 years of brand history and industry experience.

2. Complete certificates, first-class standard.

3. Stable and high level product quality.

4. Regular products, delivery within 7 days.

5. Price support, adapt to the local market.

6. Team of 37 engineers, reliable technical support.

7. Professional training, online and offline form.

8. VR live display, not limited by geography.

9. Sale and service, 12 hours quick response.

etc…